Surface/ interface science endstation

This surface analysis endstation is dedicated to UHV-based surface chemistry experiments with measurement capability including temperature programmed desorption (TPD), imaging-type XPS possessing 1D resolution of 35 μm, and near edge X-ray absorption fine structure (NEXAFS) spectroscopy. All the surface analysis instruments are located in the 14” analysis sphere. This endstation was relocated in Feb. 2017 from the focused spot (the end of the BL where it had been for 12 years) to the unfocussed spot (middle of BL) to give way to the new APXPS endstation. The X-ray spot sizes at the sample position of the endstation were measured with a Ce-doped YAG fluorescent single crystal and varied between 1.3 to 2.8 mm (FWHM) vertically but remained rather constant at 1.5 mm (FWHM) horizontally. The variation in vertical beam size has more to do with how far the exit slit (S2) is away from the sample and not so much to do with the photon energy. The rather constant horizontal size, irrespective of the X-ray energy, is due to a large separation between the sample and the only existent HFM in the beamline.

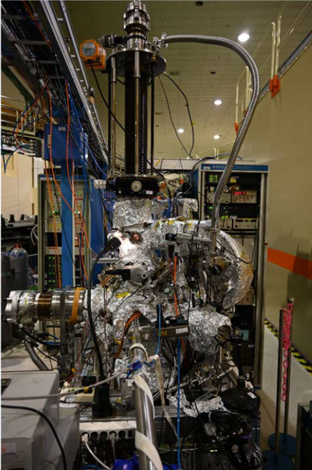

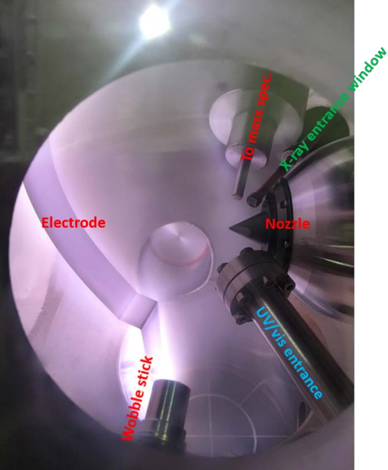

Fig.4 View of the endstation from downstream of the beamline

The electron energy analysis carried out from such modestly focused X-ray does not present a problem because a multitude of electrostatic lens tailored for difference type of excitation source are available. A SPECS PHOIBOS 150 mm analyzer outfitted with a CCD detector is the workhorse analyzer. To further cut down the X-ray spot size at the sample, a size limiter mounted on a linear translator and installed upstream to the sample can be deployed to reduce the at-sample X-ray spot size to 1 × 1 mm2 , which has proven useful to restrict the sample area examined during NEXAFS TEY and work function measurements.

X-ray absorption measurement is carried out with microchannel plate detector fitted with a set of retarding meshes to implement various electron yield detection schemes. TPS work can be carried out with a LN2-cooled, differentially pumped quadrupole mass spectrometer.

Sample handling capability

Three schemes of loading samples into the analysis sphere are implemented. First, metal or semiconductor single crystal disc can be fastened to the suitable mounting rod and reaches the analysis sphere from the top. Crystal discs can be cleaned by conventional noble gas ionsputtering followed by annealing, and sample working temperature can vary between 100 K and 1100 K. Second, for samples that do not require any additional processing, a dozen of them can be fastened to a long stick and baked in a vertical antechamber to 400 K all together before being lowered down to the analysis sphere for measurements. Third, several small samples arranged within a circle of less than 25 mm in diameter can also be transferred into the analysis sphere each time via a sample transfer mechanism, and a mild heating up to 700 K, but not cooling, of the samples is possible. Please consult beamline staff for the heatable feature of transferrable samples.

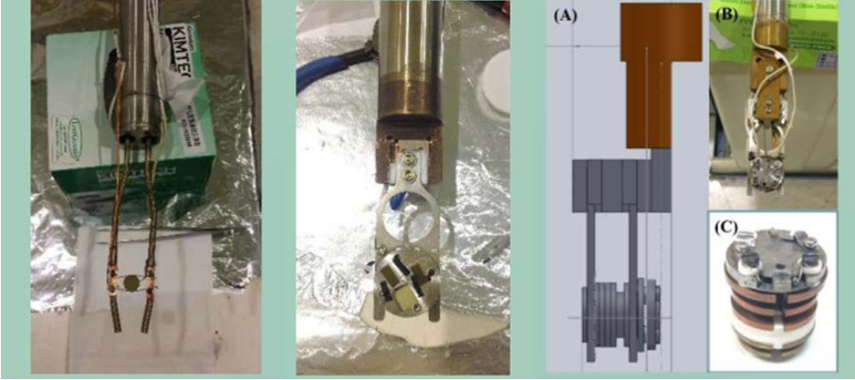

Fig. 5 Supported sample handling methods in the endstation. (Left) The holder can accept 1 cm dia. disk like single crystal that has shallow groove cut around its perimeter. Operating temperature is from 100 to 1,100 K. (Center) Exchangeable sample holder with a MDC style sample platen (25 mm. dia.). Quite a number of small-size samples can be affixed to both faces of the platen. Room temperature operation only. (Right) This transferable holder can be heated to 720 K but pratically no cooling capability. It is a delicate device developed by us and can be on loan to users by a speical arrangement.

Major equipment list

SPECS PHOIBOS 150 electron energy analyzer, flood gun (Kimball Physics), 5 keV differentially-pumped sputter ion gun (VG EX-05), mass spectrometer (300 Da, UTI 100C), home built NEXAFS detector (PEY detection), load lock sample transfer, and SpecsLab2 in XP OS for operating the analyzer.

Ambient pressure X-ray photoelectron spectroscopy (APXPS) endstation

The endstation is designed primarily for performing XPS measurements of solid surfaces interacting with gasses at elevated pressure up to 10 mbar. The endstation is the only one in Taiwan and has been open to users since September 2017. In contrast to the conventional Xray photoelectron spectroscopy that is performed in an environment better than high-vacuum to eliminate electron-gaseous molecule scattering events, APXPS is carried out in mbar pressure range, enabling the acquisition of photoelectron signals from gas, solid surface, and liquid surface as well. The realization of this unconventional technique hinges on the successful development of sophisticated electrostatic lens of the analyzer in conjunction with elaborate differential pumping system. The technique enables an in-situ and in-operando investigation of heterogeneous reactions and allows researchers to extract the crucial information heretofore unavailable in many important research areas including catalysis, energy storage, environmental and atmospheric sciences.

NOTE: The present APXPS system is not designed for handling liquid present in the vacuum chamber. At present, photoelectron spectroscopy measurements for liquid surface and liquid/solid or electrochemical interface are not possible. The APXPS for liquid-related measurements needs to await the opening of a new APXPS beamline at TPD, scheduled to be completed in 2024.

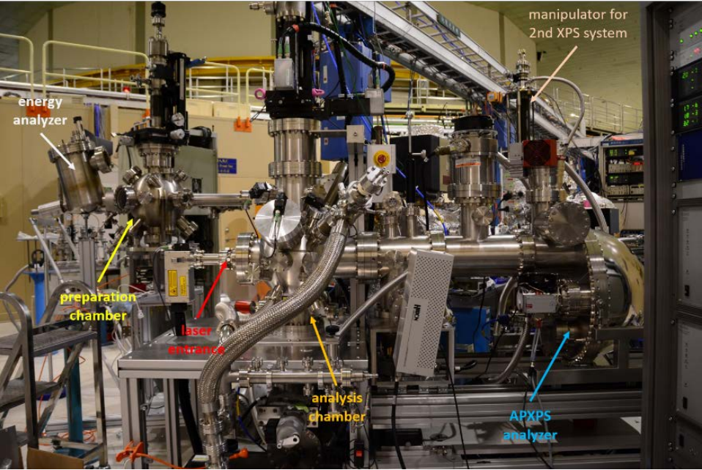

Fig. 6 Photo of completed APXPS endstation situated at the end of wide-range beamline. Xray photons is incident roughly along the direction of the overhead cable trays. A new preparation chamber with more functionality replaced the earlier preparation chamber shown in this photo in Jan. 2020. What is not shown is a gas manifold supplying gases and liquids.

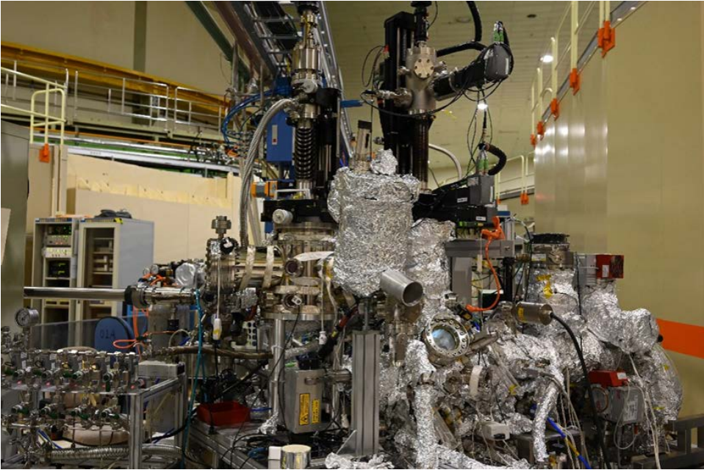

Fig. 7 An updated photo of APXPS endstation, though mostly covered with aluminum foil, complete with a new preparation chamber and gas manifold.

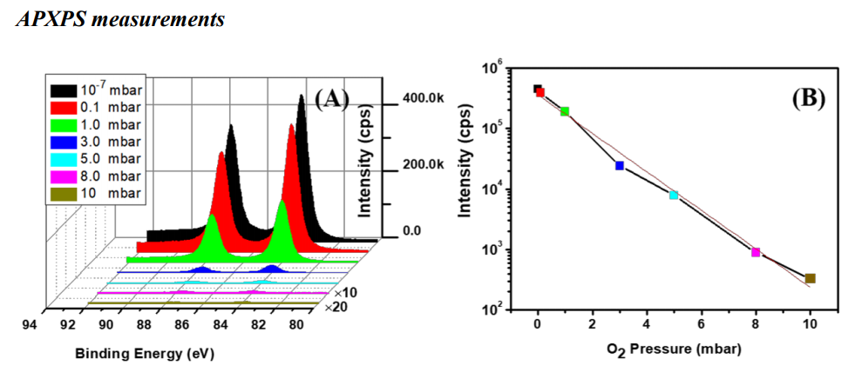

Selective commission results

Fig. 8 (A) Attenuation of XPS Au 4f signal from a gold substrate by ambient O2 gas at differnt pressure. The spectra were acquired with photon energy of 620 eV using an APXPS entrance nozzle of 300 μm in diameter with analyzer pass energy set at 20 eV. A modest overall instrument resolution of 0.27 eV was used. The X-ray incidence angle was 56.5° from the surface normal and photoelectrons were collected over a wide angular range of ±22° from the 0° direction. The X-ray intensity at the sample surface was lower due to a large separation of 80 mm between Si3N4 and the sample. This separation has been reduced down to 30 nm since the measurements. (B) The plot of intensity in logarithmic scale versus oxygen pressure. The slope in the plot yields the electron and O2 scattering cross-section of 5 Å2 for an electron energy of 535 eV.

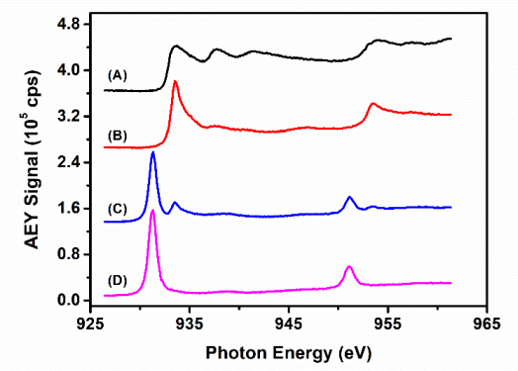

Operando XAS measurements

The APXPS endstation is also capable of performing in-situ and operando study of X-ray absorption spectroscopy (XAS) at elevated pressure up to 10 mbar, pressure-limited by the pumping speed of the system. The techniques available include AES detection using the PHOIBOS NAP analyzer and TEY detection by measuring drain current either from the sample or uniquely from entrance nozzle of APXPS analyzer. One disadvantage of performing XAS measurements in APXPS chamber is the inaccessibility of polarization dependence investigation because the sample cannot be rotated owing to its short distance of 500 μm to the nozzle.

Fig. 9 In-operando XANES spectra, acquired by using AES mode in the presence of oxygen ambient, for a copper foil successively oxidized to different degrees: (A) clean Cu, (B) Cu2O, produced by heating the foil at 473 K for 5 min in 0.1 mbar O2, (C) mixed Cu2O and CuO, more foil heating at 573 K for 10 min in 1 mbar O2, (D) CuO, formed with additional 20 min treatment. Ek = 920 eV, Ep = 80 eV.

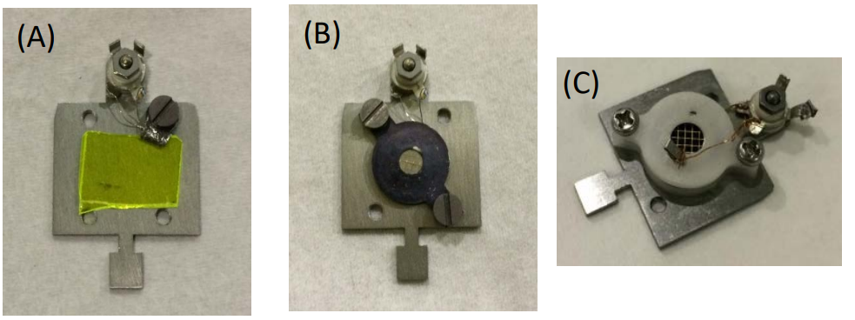

Sample handling capability

Fig. 10 (A) Planar sample can be affixed to the sample holder using four avaiable M2 screws. A pair of thermocouple wires can be seen attached to the sample. (B) Pressed powder samples (5 mm in dia.) once loaded into the central region can be secured in place with (A) (B) (C) 9 ceramic washers and a Au mesh. The gold mesh serves as an XPS energy reference as well as an electron source to alleviate the sample charging problem. (C) A solid-state electrochemical cell developed for metal-air battery study by Prof. Yi-Chun Lu’s group at Chinese Univ. of Hong Kong.

Major equipment list

APXPS chamber

SPECS PHOIBOS NAP 150 electron energy analyzer, 5 keV differentially pumped sputter ion gun (VG EX05), two-stage differentially-pumped mass spectrometer for detecting reaction products (Hiden HAL/3F RC PIC, 510 Da), NIR laser heating (150 W), solar simulator (150 W) and UV source (365 nm, 6W), RF plasma source for cleaning chamber and samples (Comet cito Plus, 13.56 MHz, 600 W), mass flow controllers (Bronkhorst ELflow), Prodigy software in Win 7 OS for operating the SPECS analyzer,

Preparation chamber

Situated between a load lock transfer and APXPS chambers. CLAM 2 triple channeltron analyze, electron gun for AES excitation source (VG LEG 63), hydrogen cracker (Oxford Applied Research TC50) for cleaning delicate samples, e-beam evaporator (SPECS EBE-1), reverse view LEED (VG RLV 900), thin film deposition controller (Inficon XTC/3).

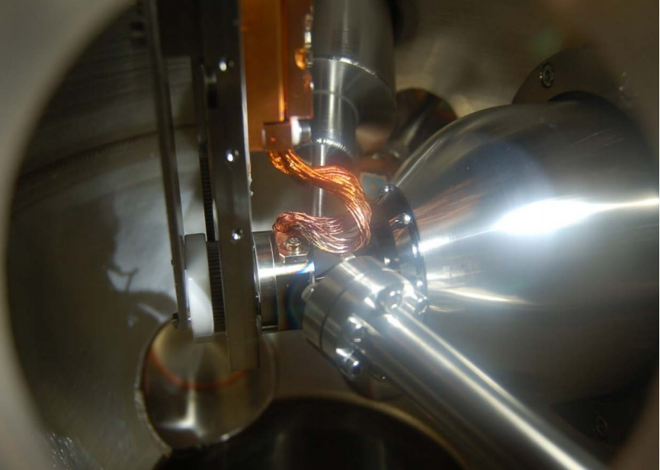

Selective photos

Fig. 11 Sample is located in a tight space during the APXPS measurement. Extreme care needs to be taken to ensure that no collision occurs during the movement of the manipulator.

Fig. 12 The inside of the chamber lit up by oxygen plasma during the cleaning of the chamber inside wall

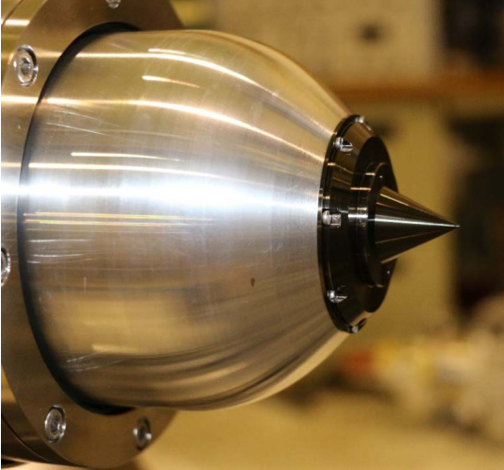

Fig. 13 Nozzle with a very small opening of variable size (now 500 μm in dia.) serves to separate the sample chamber in mbar pressure range from the prelens region of the analyzer with a pressure reduction ratio of ~ 5000.

Fig. 14 Sample manipulator has two vertically separated sample receivers. The sample mounted in the bottom receiver can be heated to 1000 K by NIR laser striking the back of the sample. The top sample receiver can cryogenically cool down the sample through the LN2 but it has no provision for heating the sample. As a result, this top receiver has not been used often.

Fig. 15 (Left) Enlarged view of the sample holder evenly seated in the receiver. TC pair is spot-welded to the edge of the holder. (Right) Solid state electrochemical cell mounted in the sample holder with the existing thermocouple wires substituted for the lead wires of twoelectrode cell.